Pattern Making 1.įoundry Tools and Equipments 1. Fundamentals of Metals and Aloys 4.įerrous Metals and Alloys 6.

#Manufacturing process by rs khurmi pdf pdf

Free PDF ebooks (user's guide, manuals, sheets) about Manufacturing processes by r s khurmi gupta pdf ready for download.Ĭhand & Company Ltd., 2. Item Description: S.įree PDF ebooks (user's guide, manuals, sheets) about Manufacturing process by author rs khurmi jk gupta pdf ready for download.

Just as sketch relations define conditions such as tangency, parallelism, and concentricity with respect to sketch geometry, assembly mates define equivalent relations with respect to the individual parts or components, allowing the easy construction of assemblies.Introduction to manufacturing process by r s khurmi R S Khurmi Are Listed Below: PDF File : Introduction To Manufacturing Process By R S Khurmi Page : 1.Ī Textbook of Manufacturing Processes Workshop Technology J K Gupta R S Khurmi. In an assembly, the analog to sketch relations are mates. The dimensions in the sketch can be controlled independently, or by relationships to other parameters inside or outside of the sketch. The parametric nature of SOLIDWORKS means that the dimensions and relations drive the geometry, not the other way around. Relations are used to define attributes such as tangency, parallelism, perpendicularity, and concentricity. The sketch consists of geometry such as points, lines, arcs, conics (except the hyperbola), and splines.ĭimensions are added to the sketch to define the size and location of the geometry. Building a model in SOLIDWORKS usually starts with a 2D sketch (although 3D sketches are available for power users). Operation-based features are not sketch-based, and include features such as fillets, chamfers, shells, applying draft to the faces of a part, etc. This shape is then extruded or cut to add or remove material from the part.

Shape-based features typically begin with a 2D or 3D sketch of shapes such as bosses, holes, slots, etc. They are the shapes and operations that construct the part. Features refer to the building blocks of the part. SOLIDWORKS allows the user to specify that the hole is a feature on the top surface, and will then honor their design intent no matter what height they later assign to the can. Trusted by teams at Apple, Ogilvy, & NASA.

#Manufacturing process by rs khurmi pdf software

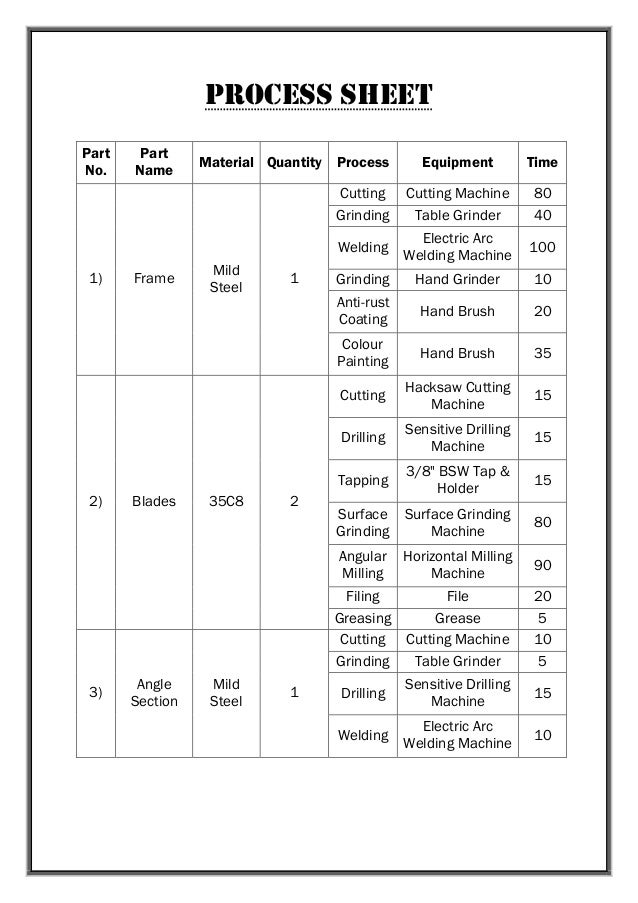

The fast, simple way to schedule people & other resources online! Virtuagym's software will automate your scheduling and booking system, you're guaranteed to save hours of your time. Let your members book classes at their own convenience and minimize no-shows. Manufacturing and technical staff in industry must know the various manufacturing processes, materials being processed, tools and equipments for manufacturing different components or products with optimal process plan using proper precautions and specified safety rules to avoid accidents.īy giving them the power to book their own sessions, it prevents mistakes and takes away frustration. Manufacturing is the backbone of any industrialized nation. Mechanics- RS khurmi 25) Manufacturing Process by hassan abdel 26). 23) Strength of Materials – Bhavikatti: 24) Engg. Best study materials for paper 2, locus classes study materials. Rao, manufacturing technology by p n rao ebook free download, manufacturing technology by p n rao.

Rao, manufacturing technology 3rd edition by p.n rao, manufacturing technology 3rd edition by p.n rao pdf, manufacturing technology book by p.n. Manufacturing technology (vol i ) by p n rao (mcgraw hill), manufacturing technology - vol. This flexibility is mainly due to a modular design of both the screw and the barrel (see figure 1. Twin-screw extrusion is a very flexible process. Be varied, it is possible to adapt this machine to the manufacturing of a large variety of thermoplastic compounds.

0 kommentar(er)

0 kommentar(er)